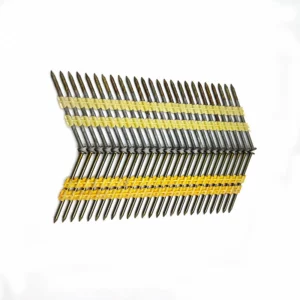

21-degree paper collated framing nails, often referred to as 21-degree framing nails, are commonly used in construction and carpentry for various applications. These nails are specifically designed to be used with a pneumatic nail gun that accepts 21-degree plastic collated nails. Here’s a closer look at the role and benefits of 21-degree paper collated framing nails:

- Framing Applications: 21-degree framing nails are primarily used for structural framing tasks, such as building walls, installing floor joists, constructing roofs, and framing other load-bearing structures. These nails are suitable for heavy-duty applications that require secure and reliable fastening.

- Enhanced Holding Power: The 21-degree nail angle allows for a greater surface area contact between the nail head and the material being fastened. This design provides enhanced holding power, making it ideal for framing applications where strength and stability are crucial.

- Compatibility with Nail Guns: 21-degree framing nails are collated with plastic strips that hold the nails together, allowing for efficient and rapid installation using a pneumatic nail gun. The plastic collation keeps the nails aligned and prevents jamming, ensuring smooth and continuous operation.

- Easy Loading and Feeding: The plastic collation of 21-degree framing nails allows for easy loading into the nail gun’s magazine. The collation strip also facilitates smooth feeding of nails into the nail gun, minimizing downtime and increasing productivity on the job site.

- Versatility: 21-degree framing nails are available in various lengths, diameters, and coatings to accommodate different construction needs. Whether you’re working with softwoods, hardwoods, or engineered lumber, you can find 21-degree framing nails suitable for the specific requirements of your project.

- Code Compliance: Building codes often specify the use of specific nails for structural framing purposes, and 21-degree framing nails are commonly accepted and compliant with these regulations. They meet the necessary strength and performance requirements to ensure the structural integrity of the framed components.

When using 21-degree framing nails, it is important to follow the manufacturer’s guidelines and safety instructions for the nail gun 21 degree paper collated framing nails and associated equipment. Proper training, including understanding the appropriate nail length and placement, is essential to ensure the integrity and safety of the framing work.

Overall, 21-degree paper collated framing nails play a significant role in construction and carpentry projects, providing reliable and efficient fastening for framing applications. Their compatibility with nail guns, enhanced holding power, and versatility make them a preferred choice for professionals in the industry.

When it comes to 21 degree paper tape framing nails, here is some further information:

- Nail Shank Options: 21-degree framing nails are available in different shank types, such as smooth shank and ring shank. Smooth shank nails have a plain surface and are commonly used for general framing applications. Ring shank nails have ridges along the shank, providing increased holding power and resistance to withdrawal. The choice of nail shank depends on the specific requirements of the project and the type of material being fastened.

- Coating Options: Framing nails can come with various coatings to enhance their durability and resistance to corrosion. Common coating options include hot-dip galvanized, electro-galvanized, and stainless steel. Galvanized coatings provide protection against rust and are suitable for exterior applications or areas with high moisture content. Stainless steel nails offer excellent corrosion resistance and are often used in environments with extreme conditions or for applications requiring a high level of durability.

- Efficiency and Speed: Using a nail gun with 21-degree paper collated framing nails significantly increases productivity and efficiency on the job site. The pneumatic nail gun allows for rapid and consistent nail placement, reducing the need for manual hammering and saving time and effort.

- Job Site Safety: When using 21-degree framing nails, it’s essential to follow proper safety precautions. This includes wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. It’s also important to ensure that the nail gun is operated safely, following manufacturer guidelines and keeping fingers and other body parts clear of the nail gun’s firing area.

- Availability: 21-degree framing nails are widely available at hardware stores, home improvement centers, and specialized construction supply retailers. They are typically sold in boxes or collated strips suitable for use with nail guns.

- Consult with Professionals: If you’re uncertain about the specific nail requirements for your project, it’s advisable to consult with professionals such as contractors, carpenters, or experienced individuals in the construction industry. They can provide guidance on the appropriate nail type, length, and other considerations based on the specific needs of your project.

Remember, proper installation techniques and adherence to building codes and regulations are crucial for ensuring the structural integrity and safety of the framing work. Following recommended practices and using quality 21-degree framing nails will help create sturdy and reliable structures.